Purple film GB 8138-2009

This standard supersedes GB/T 8138-1987 Purple Film.

Compared with GB/T 8138-1987, this standard mainly changes as follows:

-Normative references are added;

-- Adjust the value of the thermal time (thermal life) indicator in the technical requirements;

-The requirements for mandatory test, optional test and note in the technical requirements are deleted;

-The "orpiment" indicators and requirements in the technical requirements are added;

-Chapter 5 "Sampling" is added, and the content of sampling in the inspection rules is deleted;

-The provisions on inspection classification and inspection items in the inspection rules are added;

-Requirements for ambient temperature for storage and transportation are added;

This standard is proposed by the State Forestry Administration.

This standard is under the centralized management of the Institute of Forest Products Chemical Industry, Chinese Academy of Forestry.

This standard is drafted by Institute of Forest Chemical Industry, Chinese Academy of Forestry.

Participated in the drafting of this standard by: Yunnan Yunxian Bushuailin Chemical Factory, Kunming Forest Products Chemical Co., Ltd., Kunming Suhua Biotechnology Co., Ltd.

Main draftsmen of this standard: Wang Yongmei, Chen Jiahong, Wu Dongmei and Wu Zai Song.

The previous versions replaced by this standard are:

--GB/T 8141-1977

1 Scope

This standard specifies the technical requirements, sampling, test methods, inspection rules, marking, packaging, storage and transportation of purple film.

This standard applies to granular shellac and shellac gel processed by hot filtration method and solvent method.

2 Normative references

The terms in the listed documents are referenced by this standard and are the terms of the standard. For dated references, all subsequent amendments (excluding errata) or revisions are not applicable to this standard. However, parties who have reached agreements based on this standard are encouraged to study whether the latest versions of these documents can be used. For undated references, the latest version is applicable to this standard.

GB/T 8142-2008 Methods of sampling shellac products

GB/T 8143-2008 Methods for inspection of shellac products

3 Terms and definitions

For the purposes of this standard, the following terms and definitions apply.

3.1 purple film shellac

Raw shellac or granular shellac processed by hot filtration and solvent methods without decolorization and dewaxing.

4 Technical requirements

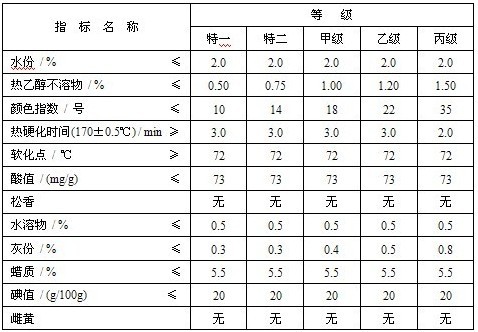

Purple film at all levels should meet the following technical indicators.

5 Sampling

Sampling and sample preparation shall be carried out according to GB/T 8142-2008.

6 Test method

Determination of moisture in 6.1

The test shall be carried out in accordance with Chapter 3 of GB/T 8143-2008.

6.2 determination of insoluble matter in hot ethanol

The test shall be carried out in accordance with Chapter 4 of GB/T 8143-2008.

Determination of 6.3 color index

The test shall be carried out in accordance with Method 2 in Chapter 5 of GB/T 8143-2008.

6.4-Determination of thermal hardening time

The test shall be carried out in accordance with Chapter 11 of GB/T 8143-2008.

Determination of softening point of 6.5

The test shall be carried out in accordance with Chapter 16 of GB/T 8143-2008.

Determination of acid value of 6.6

The test shall be carried out in accordance with Chapter 12 of GB/T 8143-2008.

Determination of 6.7 rosin

The test shall be carried out in accordance with Chapter 7 of GB/T 8143-2008.

6.8-Determination of water-soluble matter

The test shall be carried out in accordance with Chapter 10 of GB/T 8143-2008.

Determination of ash content in 6.9

The test shall be carried out in accordance with Chapter 9 of GB/T 8143-2008.

Determination of wax in 6.10

The test shall be carried out in accordance with Chapter 6 of GB/T 8143-2008.

Determination of iodine value of 6.11

The test shall be carried out in accordance with Chapter 13 of GB/T 8143-2008.

Examination of 6.12 Orpiment

The test shall be carried out in accordance with Chapter 8 of GB/T 8143-2008.

7 Acceptance rules

7.1 inspection classification

Product inspection includes delivery inspection and type inspection.

7.2 inspection items

7.2.1 Delivery inspection items include moisture, hot ethanol insolubles, color index, thermal hardening time and softening point.

7.2.2 The type inspection items include all items listed in Table 1.

7.2.3 Type inspection shall be carried out under any of the following conditions:

a) During normal production, the type inspection shall be carried out at least once a month;

B) Major changes of original and auxiliary materials and production process;

c) Production recovery after long-term suspension;

d) When the type inspection is requested by the quality supervision organization or the customer.

7.3 Group Batch Rule

The products of the same production batch constitute 1 batch.

7.4 Judgment Rules and Re-inspection Rules

7.4.1 It shall be inspected by the quality inspection department of the manufacturer. Each batch of purple film shall meet the requirements of this standard and be accompanied by a quality certificate in a certain format.

7.4.2 If any index of the test result does not meet the requirements, the sample shall be sampled again from the double sample and the unqualified index shall be inspected again. If it still does not meet the requirements, the product is unqualified.

7.4.3 If there is any dispute over the inspection results of purple film by both parties, it shall be proposed within three months after the arrival of the goods. Both parties can jointly sample three copies according to the sampling method of this standard, one copy for each party, and the other copy shall be entrusted to an inspection department with corresponding qualification for arbitration analysis.

8 Marking, packaging, storage and transportation

8.1 product mark

The packaging shall indicate the product name (purple film) and trademark, the standard label, production date or production number, quality grade, net weight, enterprise name, detailed address, telephone number, etc.

8.2 packaging

8.2.1 Purple film shall be packed in wooden cases or other packaging, lined with a layer of kraft paper.

8.2.2 The net weight of each box of purple film is 25KG.

8.3 storage

8.3.1 The product should be placed in a dry, ventilated room with ambient temperature below 25 ℃ to avoid caking.

8.3.2 The increase in the color index of the product within one year from the date of delivery shall not exceed No. 6.

8.4 transportation

During the transportation of the product, it is strictly prohibited to bask in the sun, rain and near heat sources and humid places, and the temperature in the transportation vehicle should be lower than 25 ℃.